CutPRO X 106

Rotary Die-Cutter

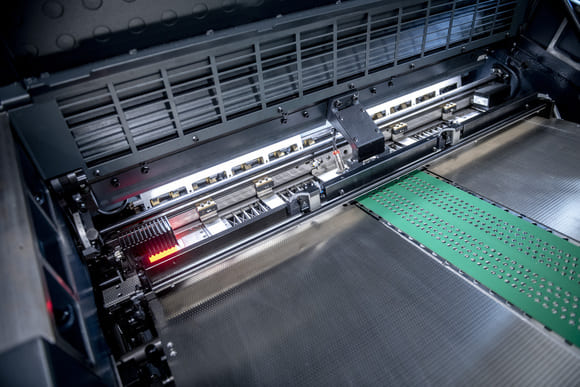

The CutPRO X 106 offers top performance in inline die-cutting and customised solutions for future-oriented in-house production.

Outstanding Features of the CutPRO X 106

Rotary Die-Cutter

- One machine, 3 segments, 5 technologies

- Maximum performance up to 16,000 sheets/h

- Ultimate productivity based on the Rapida medium-format press series

- Separate process units for unrivalled flexibility

- Exceptional die-cutting quality thanks to outstanding register accuracy

- Significant cost savings thanks to minimal waste and quality costs

Ready for The Next Step – The Rotary Die-Cutter CutPRO X 106

Developed on the basis of the Rapida medium-format press series, it incorporates the very latest die-cutting technology for a virtually boundless scope of applications: Die-cutting, embossing, creasing, perforating, Braille texts on pharmaceuticals packaging, elegant presentation folders or inmould labels for paint buckets – everything is possible. After all, the CutPRO X 106 is tailored precisely to your future-oriented in-house production needs.

You can choose from a whole range of different configurations and equipment packages. Depending on your particular requirements and applications – for products of the highest quality, die-cut with absolute precision and care.

- Absolute sheet feeding precision and production speeds up to 16,000 sheets/h thanks to innovative DriveTronic dedicated drive technologies

- Process reliability and maximum flexibility, even with demanding substrates

- Fastest possible makeready with full preset capabilities for all air and format settings

- Koenig & Bauer only

- Significant waste savings thanks to reliable, marking-free sheet alignment, irrespective of substrate thickness

- Stable production processes and high availability thanks to fewer stoppages and exact infeed register

- Precision-ground magnetic cylinder for fast, exact and tool-free positioning of the die-cutting tools

- Ultimate accuracy and perfect die-cutting results thanks to precise setting of the die-cutting pressure in 1 µm steps

- Convenient, user-friendly mounting

- of complete formes, using the “click & cut” principle

- individual die segments (e.g. Braille texts) can be positioned freely without the need for tools

- Maximum performance in the production process thanks to gentle, air-cushioned sheet guiding

- All sheet travel functions can be controlled from the machine console, with full preset capabilities for repeat jobs and individual fine adjustment to suit every substrate

- Universal gripper systems for reliable sheet transfer and absolute register accuracy at all production speeds and substrates

- Common unit design for maximum substrate flexibility from 0.03 mm film to 0.6 mm board

- High ease of operation thanks to fast and precise positioning of the die-cutting forme

- Fastest possible makeready and job changeovers for maximum productivity

- Venturi sheet guiding system for the broadest range of substrates, including particularly sensitive materials

- Dynamic sheet brake of the Rapida 106 X ensures “picture-perfect pallets” with absolutely straight pile edges at die-cutting speeds up to 16,000 sheets/h

- Fastest possible makeready thanks to full preset capabilities

Perfect Flexibility for Every Application

Packaging

The CutPRO X 106 rotary die-cutter offers die-cutting technology geared to greater diversity and cost-aware finishing in the packaging sector: With a multitude of configuration variants and options always the ideal solution for your needs.

Commercial

The CutPRO X 106 rotary die-cutter offers die-cutting technology geared to greater diversity and cost-aware finishing in the packaging sector: With a multitude of configuration variants and options always the ideal solution for your needs.

Label

The CutPRO X 106 rotary die-cutter incorporates the latest die-cutting technology for label production. Features not only developed for processing of inmould films from 30 μm, but also for many other label materials.

Technical Data of the CutPRO X 106

| Standard | Optional | |

|---|---|---|

Max. Sheet Format | 740 x 1,060 mm | 750 x 1,060 mm, 780 x 1,060 mm |

Min. Sheet Format Cardboard | 340 x 480 mm | - |

Min. Sheet Format IML | 480 x 480 mm | - |

Gripper Margin | 10 ± 1 mm | - |

Suitable Substrates | 0.03 - 0.6 mm | - |

Pile Height Feeder | 1,300 mm | - |

Pile Height Delivery | 1,200 mm | - |

Max. Production Speed1) | 15,000 sheets/h | 16,000 sheets/h |

Die-Cutting Margin | 17 mm | 13 mm |

1) Dependent on individual processing parameters, e.g. inks and substrates used | ||

Interested in the CutPRO X 106 SB?

Fields marked with a * are mandatory. You will receive an e-mail confirming your contact request after you have filled out this form.

Related Products

Rapida 106 XMedium Format Sheetfed Offset Printing Press

The Rapida 106 X is the most efficient and sophisticated 740 x 1,060 mm sheetfed offset press ever built by Koenig & Bauer.

VariJET 106Digital Sheetfed Printing Press

The VariJET 106 marries the time-tested press engineering of the Rapida 106 with the latest generation of single-pass inkjet printing technology of Durst.

Omega AllproFolder Gluer

Omega Allpro gluers are capable of producing the most complex range of carton styles, minimising make-ready and maximising productivity and profitability.

English

English

Deutsch

Deutsch